Make your project happen.

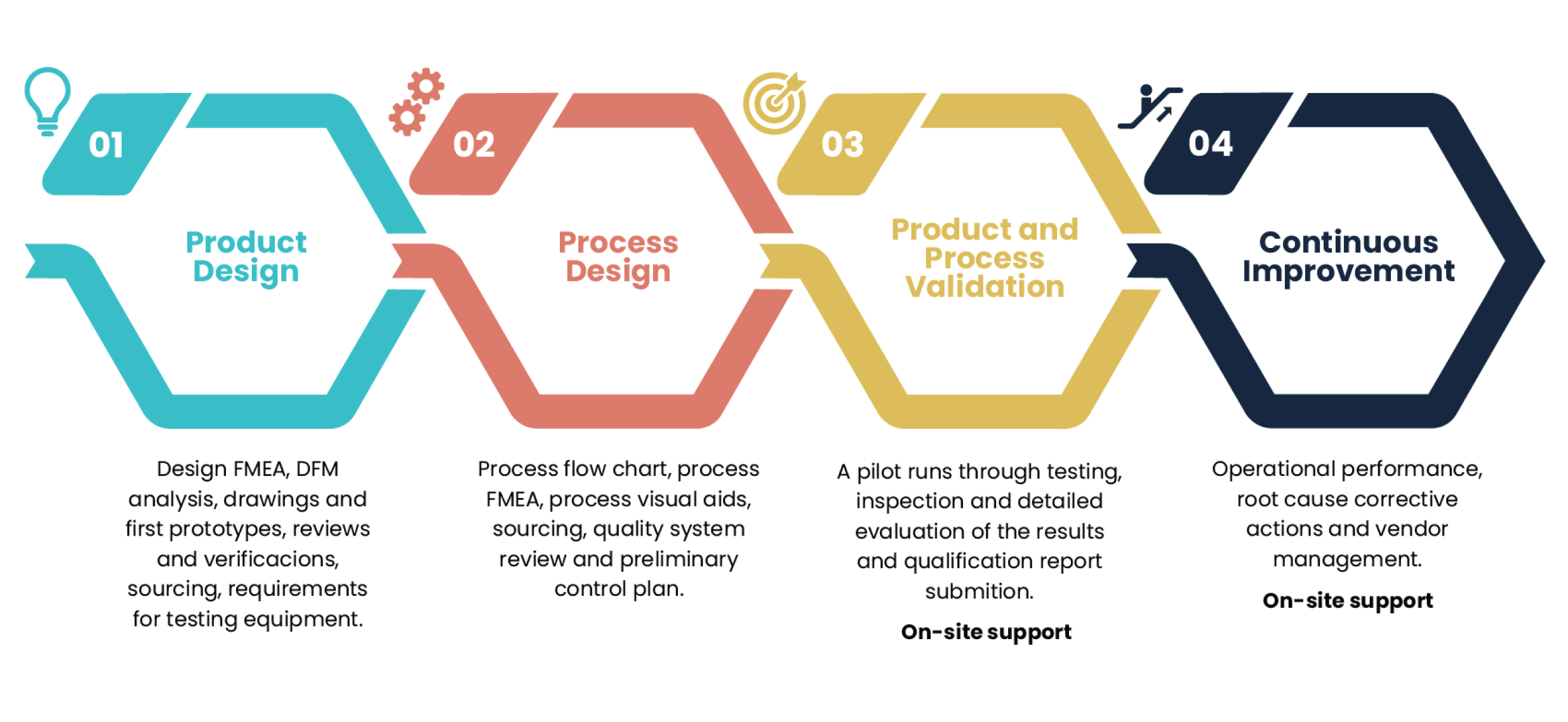

Product and vendor qualification services help our customers improve their time to market in different industries. Our proven approach ensures quality, consistency, and reliability. We qualify your parts and the process and ensure all controls and manufacturing practices are followed.

Implementing manufacturing quality control aims to produce products that conform to industry, company, and consumer expectations every time. This system monitors everything from the manufactured part to the employees that put them together.

Quality control in manufacturing is any effort to review the quality of products to identify and eliminate defects. Ideally, the flaws will be found and fixed before the products ever reach the hands of consumers, but in some cases, a defect can be found that will trigger a recall or other effort to fix the issue after the product has been delivered.

Quality control is critical in most modern manufacturing facilities because such a high product volume is made quickly. If a machine is causing a defect, it can result in thousands of products being produced that need to be up to the necessary standards.

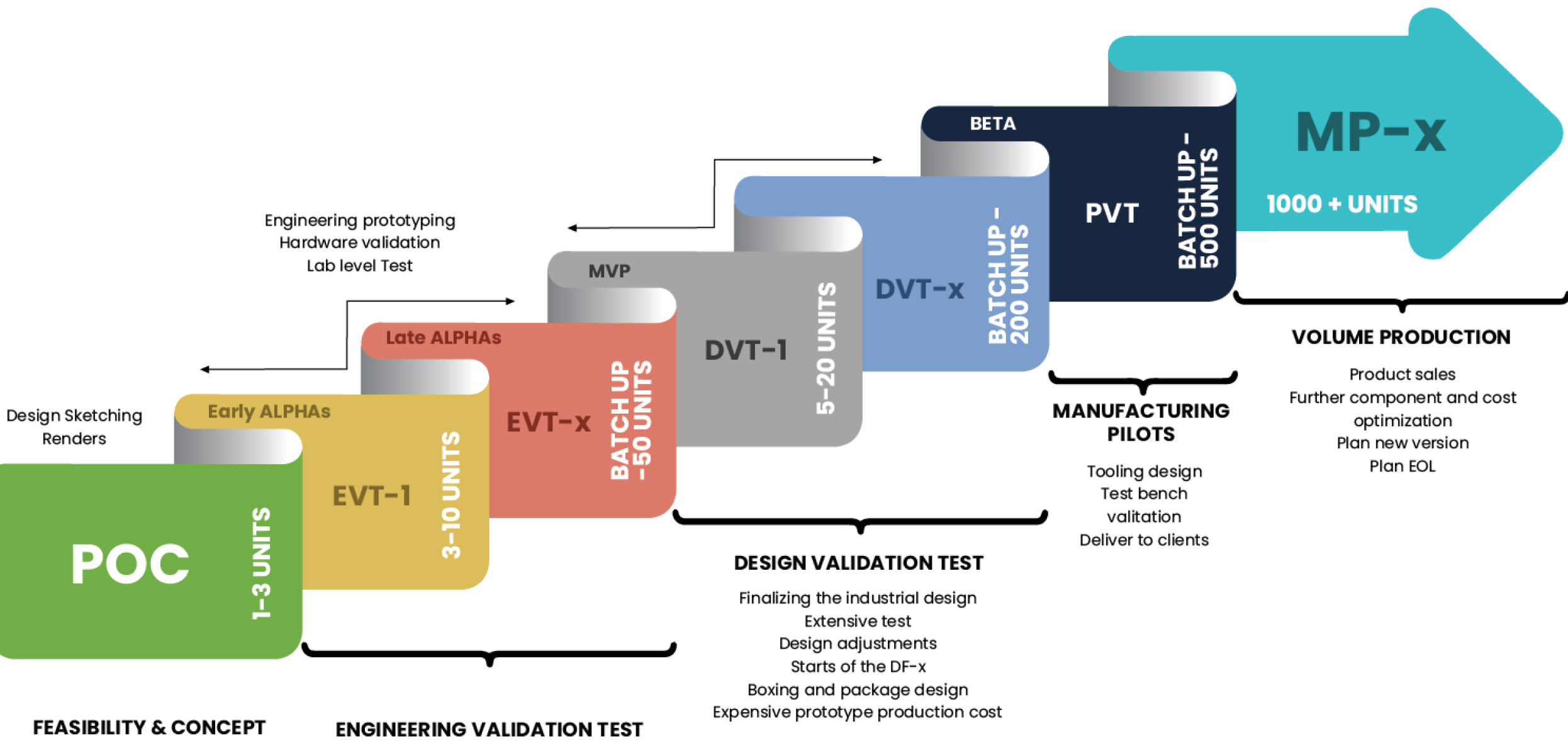

Product & Process Model